PGG Wrightson Seeds needed a reliable way to improve air quality and create a safer working environment at their Gisborne seed processing site. Dust generated from the gravity tables was the key concern, so they engaged Vortex Engineering Group to design and deliver a new clean air extraction system.

Taylors Manufacturing was responsible for producing the core components of the solution, including the extraction fan and custom-designed hoods. We partnered with Airtight, who supplied the baghouse and discharge system, ensuring all parts were well-matched, efficient, and seamlessly integrated.

What Taylors Delivered

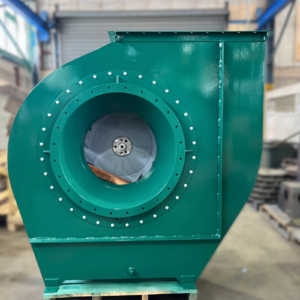

- 75 kW FA1120 Extraction Fan

We manufactured a FA1120 extraction fan with a 75-kW motor and an ABB variable speed drive. This lets the operators adjust airflow easily and helps the system run more efficiently.

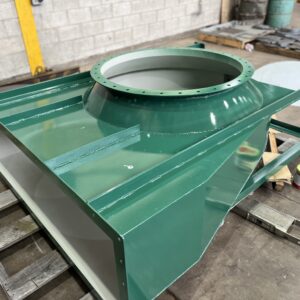

- Custom Extraction Hoods

Taylors built two hoods to sit above the gravity tables. These collect dust right at the source and move it into the ducting system.

This project shows a collective collaborative effort from the Vortex Engineering Group.